3D Printers Don't Fix Themselves:

How Maintenance is Part of Digital Fabrication

Blair Subbaraman and Nadya Peek, University of Washington

Slides: https://rb.gy/xuvkf

July 14, 2023

Hi! I'm Blair, and today I'll be talking about our work 3D Printers Don't Fix Themselves: How Maintenance is Part of Digital Fabrication. Our paper is interested in how practitioners learn and enact the embodied skills necessary to maintain digital fabrication machines, and how we might develop future systems which are accountable to the messy realities of maintenance.

We're looking here at a video posted to an online printer repair communit, on the site Reddit. We can make out in the video that the filament doesn't seem to be sticking to the printer bed. What's supposed to be printed is a calibration print, but as we can see in the final frame here, something has obviously gone awry.

Expected fabrication outcome based on model

Actual outcome from 3D printing (from r/FixMyPrint )

For owners of machines like FDM 3D printers, on-demand access to precision parts is a reality, but this reality also entails the work required to maintain a machine. Parts have to be calibrated, cleaned, repaired, and replaced. While software settings can be repeated, reverted, and refined, the condition of the machine ultimately determines physical consequences for fabrication processes. In this work, we look to maintenance practices to expound the embodied dimensions of 3D printing practice.

Home and hobbyist 3D printing is a particularly promising site to begin understanding current digital fabrication machine maintenance, since 3D printing has grown immensely in popularity in the past

decade, providing many sites of practice. In our work, we specifically focus on FFF 3D printers, given their widespread adoption.

How do practitioners maintain their 3D printers?

Stemming from these intitial insights, we ask the research question: How do practitioners maintain their 3D printers? We are interested in how practitioners gain the embodied knowledge necessary to perform maintenance work without the presence of a process expert, and what tools help or hurt in conducting maintenance. We treat 3D printer maintenance as all the work performed by operators to keep printers running well. This approach intersects with several related categories of labor, like repair, calibration, tuning, troubleshooting, and standard operating procedures; by adopting a comprehensive understanding of 3D printer maintenance, we can make connections between interrelated pro- cesses.

To gain empirical insight into this question, we begin with observations of the subredded FixMyPrint, where posts run the gamut from mechanical repair through custom firmware updates. We then conducted interviews and fielded survey responses from members of this community. The community had about 67k members at the time of our study and has since grown to over 100k. Here I'm briefly scrolling through the top posts of this past month. We can see that posts generally include images or a video; in the selection shown here, we can see a question converning aesthetics, or the wavy effect seen on a print, a question concerning mechanical adhesion on a print, on one considering the flow of filament from the nozzle of the machine. And so already we see a breadth of issues that negotiate printer hardware and software.

Participant Experience (years) FFF Printer(s)

P1

2.5

Ender3 Pro

P2

0.5

Artillery Genius, custom built coreXY

P3

1

Ender3 Pro, Ender5, Dremel 3D20, Anet ET4 X

P4

2

Ender3 Pro, Ender5, Anycubic i3 Mega, Creality CR-10

P5

4

Prusa i3 MK3S+

P6

1

Ender3 Pro, Creality CR-6 SE

P7

1

Ender5, Ultimaker S5

P8

0.5

Ender3

P9

1

Monoprice Mini, Prusa i3 MK3S

P10

2

Ender3 Pro, Prusa Mini

Overview of interview (left) and survey (right) participants

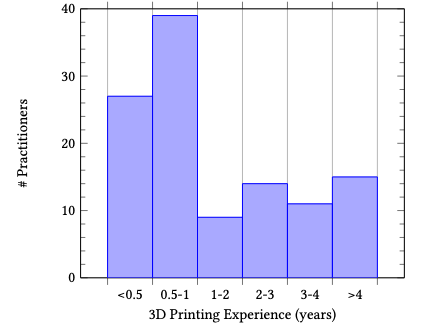

We recruited 10 participants from FixMyPrint and a related community for semistructured interviews. All participants reported sole responsibility for the maintenance of at least one 3D printer, and varied in 3D printing experience from half a year to 4 years. An overview of our interview participants and their printers are shown on the left here.

After the start of our interviews, we observed that each practitioners’ fabrication practice involved unique configurations of hardware and software which informed practitioners' maintenance routines. We sought additional open-ended responses via a survey and 92 responses.

Participant Experience (years) FFF Printer(s)

P1

2.5

Ender3 Pro

Our interviews were all conducted over Zoom, and participants shared their printing workspaces where possible. For example, P1's setup is shown here, including a printer enclosure which was actually one of their first 3D printing projects.

Routines | Repairs | Refinements | Reconciliations

We conceptualized 4 main themes which we situate within digital fabrication practice

Routines | Repairs | Refinements | Reconciliations

including the ad-hoc routines which practitioners develop around physically prepping their machines,

Routines | Repairs | Refinements | Reconciliations

machine repairs where operators gain confidence through physical disassembly and reassembly,

Routines | Repairs | Refinements | Reconciliations

how practitioners use tangible output to refine settings

Routines | Repairs | Refinements | Reconciliations

and finally how practitioners reconcile software which prioritizes digital over tangible practice to manage maintenance concerns. For more detail I of course encourage everyone to check out the full paper, And for the rest of my time, I'll start to dive the nuance of each theme and then discuss some of their implications.

Practitioners ensure reliable fabrication outcomes with ad-hoc procedures

Our participants explained how they ensure reliable fabrication outcomes through ad-hoc procecudes. These routines formalize tacit understandings of the fabrication process.

Practitioners ensure reliable fabrication outcomes with ad-hoc procedures

Cleaning

So like every five, six prints, you gotta take [the textured

sheet] off and clean it. Like I mean, clean it... with soap and water and then scrub it off with alcohol and put it

back.

- P4

Mechanical Tune-ups

I pay particular attention to vibrations, and sort of resonant sounds of the printer itself. If I notice that the

printer is vibrating quite a bit, and it’s almost acoustically amplifying the vibrations from the motors and

whatnot. That usually tells me there might be something

loose.

- P5

These routines include tasks which might usually be overlooked as unintersting or boring, like cleaning and tightening screws. For example, all of our participants note the importance of cleaning the build plate of their printer with soap, water, alcohol, or other chemicals. We find that scheduling times to do this work reflects broader attitudes towards printing, including compromises between convenience and quality.

Over longer timescales, practitioners discuss how mechanical parts need to be tightened and tensioned. P6 described how they're experienced enough to give the machine a visual inspection, where they can check for things like the tensioning of the belts or loose screws. While the printer is running, they're attentive to audiory cues, saying:

This sort of tacit knowledge of the machine is built over time, and not easily translated from directive documentation.

Altogether, these mundane acts draw attention to wide assortment of tasks which sustain digital fabrication practice.

Practitioners gain confidence with machines through mechanical intervention

Compared to routine maintenance, we found that repairs which require more niche skills and parts are an important opportunity for practitioners to gain knowledge and confidence with their machines.

Practitioners gain confidence with machines through mechanical intervention

[My first printer was] just kind of a black box. I didn’t really understand what was going on inside.”

- P9

P9's first printer came fully assembled. They described using the machine cautiously in fear of breaking something, calling it a 'black box'. While this approach to printing worked for a while, things came to a head when they got a clog in the hotend of their printer. This issue required manual intervention. While the repair in this case was ultimately unsuccessful, they say that physical intervention, as well as the process of asssembling a new printer themselves, gave them confidence to work with the machine more closely:

Practitioners gain confidence with machines through mechanical intervention

You understand more what’s going on. And you get a little more confidence with the mechanics of the machine. I realized oh, the z-axis works by the motor turning this lead screw... And it’s just that simple.

- P9

3D printer assembly, disassembly, and repair brings into focus sense-making processes not usually accounted for when printing a model. Where the stakes of a failed print are often lost time or material, repair risks the machine entirely.

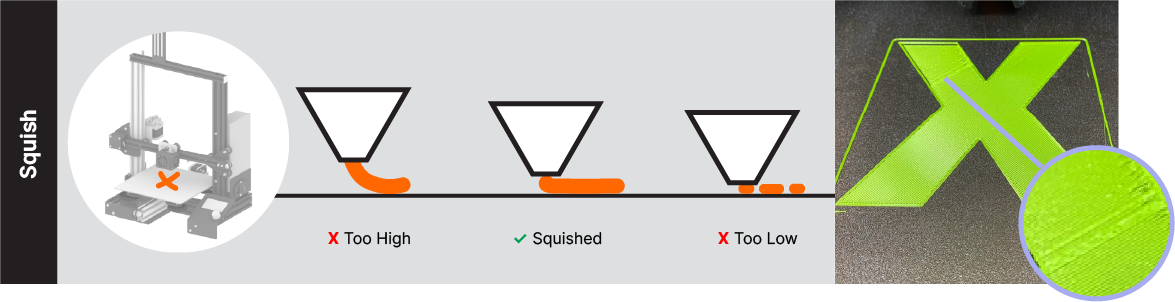

Practitioners use tangible output to tune prints

We found that practitioners spend considerable energy fine-tuning

settings for the best quality prints. While this generally involves setting digital paramters, this process is ultimately guided by evaluating physical output. We find this perfective maintenance illuminates broader connections with other physical maintenance routines.

Practitioners use tangible output to tune prints

Because you can usually tell like when you’ve been

doing it for a while... if the layer’s going down right. If

it’s squished just enough, if it’s not squished enough. If

it’s like more squished on one side than the other.

- P6

For example, P6 explains

how they have cultivated a vision sensitive to the subtle signals

present in the printing process. In getting the best quality prints out of their machine, they saY

quote

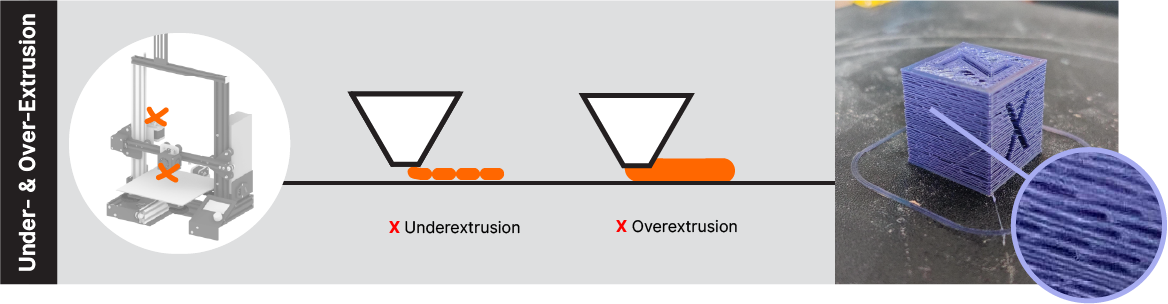

Squish refers to how tightly the nozzle is pressed against the

bed as it extrudes filament, as shown in the images shown on the screen here. Optimizing squish involves making changes to both digital parameters and the physical machine. While practitioners shared a variety of strategies to monitor and tune quality, a key takeaway here is in how real-time and tangible output is neccessary to evaluate the outcome of digital settings.

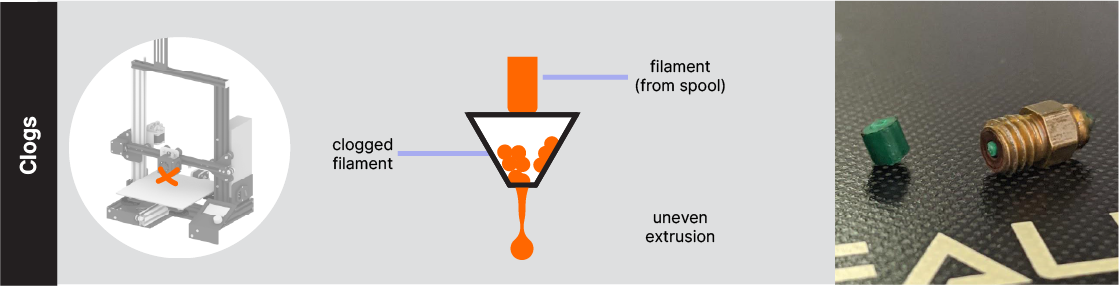

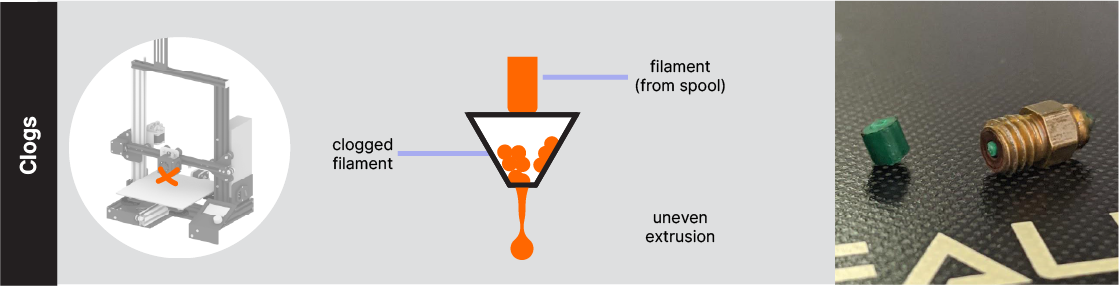

Practitioners negotiate digital software with physical practice

In the stories I've shared so far, we've begun to see how different facets of maintenance are connected.

It is not always immediately clear if a problem warrants routine maintenance, major repair, or software parameter modifications. As our final theme, I'll briefly present how our practitioners start to reconcile these interdependent considerations.

Practitioners negotiate digital software with physical practice

I noticed [the clog] because I gradually had more and

more under-extrusion. Which at first was I guess totally

fine in my eyes, because it never printed totally perfectly

before... I tried all the things like settings in my slicer before I

actually went for disassembling stuff, because it was

also kind of scary. And it seemed like a lot of work. Now

I know that it’s not that way. It’s quite easy, it just takes

a couple of screws.

- P1

An example of this is shown in this story from P1. They noticed that their printer was under-extruding, meaning less filament was being deposited than necessary as shown in this image. This didn't seem to be an issue at first, because they say their printer never printer perfectly anyways. To fix the issue, they edited software settings, but this obsucred the root problem, which was in fact a clog. They say:

quote

This example suggest ways that interfaces to set digital parameters are siloed from physical considerations, and it becomes difficult to debug printer issues when forced to think at the scale of a full model.

Machine maintenance upkeeps practice

Systems to support machine maintenance

Machine as a debugging platform

Treating physical actions on par with digital manipulations

Documenting & sharing maintenance workflows

From our findings, we argue that machine maintenance is core to digital fabrication practice, not auxiliary. While machine maintenance is often considered a temporary road block in the way of 3D printing, we see in our practitioners’ stories how maintenance helps develop skills productive to 3D printing.

Our findings also suggest that attempts to fully automate away maintenance are unlikely to account for all relevant factors. While improved machine design and software can certainly minimize uneccessary labor & frustration, a look to the history of the first numerically controlled machines and other large systems suggests a certain inevitablity to maintenance concerns.

Instead, we propose design implications which arise from treating maintenance as a core part of digital fabrication. These include treating the machine as a debugging platform so that practitioners can reason about physical output rather than abstract geometry; promoting physical engagement with the machine to make the move from manuals to manual practice less intimidating; and ways to support the documentation and sharing of maintenance workflows to support distributed practice.

While we've focused on FDM 3D printers here, we see an opportuntiy for future work which compares the maintenance of other machines which might have different stakes which condition approaches to maintenance.

3D Printers Don't Fix Themselves:

How Maintenance is Part of Digital Fabrication

Blair Subbaraman and Nadya Peek, University of Washington

Slides: https://rb.gy/xuvkf

July 14, 2023

With that, I'm happy to take any questions!